Top Benefits of Compact Steam Boiler Design for Laundry Facilities

Commercial laundry rooms are often crowded and cluttered with laundry bins waiting for the contents to be cleaned. While some industrial laundries may have suspended bags on a rail system for their client’s laundry batches, for the most part, space in an industrial laundry is tight.

We know steam is the lifeblood of a large-scale laundry facility, as it is used to heat wash water, irons, and presses. The problem with traditional steam boilers is they take up large amounts of valuable floor space and, depending on the boiler’s age, may not be entirely reliable or efficient to run.

This blog looks at how Miura’s compact steam boiler design can significantly benefit the daily operations of a busy commercial washroom.

Who Says Size Doesn’t Matter?

Time and real estate are money for a large-scale laundry operation; the more bins you can receive and wash in a day, the more revenue you earn. You’ll be happy to learn that modern steam boilers are a far cry from their bulkier and space-hogging predecessors.

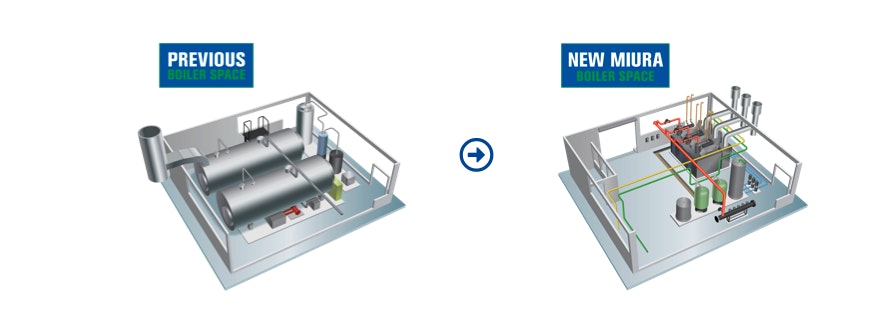

While older firetube boilers are designed with enormous pressure vessels for adequate heat transfer to produce steam, the steam boilers of today are compact and space-saving while still having as much power.

Smaller Footprint, Same Steam Output

Miura’s modular on-demand steam boilers use a “once-through” fin tube design to heat smaller volumes of water quickly. This allows them to start producing steam from a cold start in five minutes or less. The same low-water volume design means they can also shut down quickly if a laundry facility’s steam demand drops, which increases efficiencies and cost savings.

Our boilers’ vertical design means they have a much smaller footprint than a traditional system. But don’t let their size fool you; three compact Miura LX-200 gas-fired steam boilers have the same horsepower as two conventional 300-HP firetube boilers while still taking up less space.

Our modular systems also help maintain N+1 redundancy. Unlike a traditional boiler system, which requires full system redundancy in case the main boiler fails, only one of our modular units is needed as a backup.

Keeping Up With Fluctuating Steam Demands

A Miura boiler’s modular design isn’t just for decluttering a boiler room. By breaking a large boiler into smaller, compact units, you can control your steam output to meet variable steam load demands while reducing start-up loss and increasing overall efficiencies.

Say there’s a lull in operations because of a quieter-than-normal business day. Your boiler operator would have still had to come in early to fire up your old steam boiler, regardless of how much laundry there was to wash. The exact amount of fuel would need to be used to heat the same amount of water to produce the steam you need – you just wouldn’t use it all.

With multiple smaller boiler units in your boiler system, only those boilers that are needed to meet steam demand for the day come on, significantly reducing waste. If a sudden influx of laundry bins comes through your washroom door, standby boilers automatically switch on, with no assistance from your personnel.

Miura Boilers On the Job at City Laundering Company

The multi-generation family-owned City Laundering Company in Oelwein, Iowa, replaced its traditional system with an LX-Series steam boiler to match growing demand while increasing efficiencies and safety.

Watch the full video below to learn how Miura’s boilers helped the team at City Laundering go from 200 to 500 wash loads a day.

You’ll also find out how Miura’s water tube steam boilers are easy to operate, efficient, safer by design, and simple to install.

Contact one of our boiler experts today to assist with your commercial laundry facility’s steam generation needs.